My History with Scalawag

In late 2023, I began searching for the right sailboat to purchase. I started at the Annapolis Boat Show, where I talked to multiple sailing influencers, boat owners, and captains about their favorite models, makes, and styles of sailboats. I spoke with liveaboard experts, past mentors, and current clients. These are all connections I grew as a motivated and young professional in the maritime industry.

For example, thinking back to my time at Riverside Marina, I drew heavily from the experience in the buying process that I gained working under Tony Tumas, the senior yacht broker, selling for their Jeanneau and Beneteau fleet. I witnessed and assisted in over $3 million in yacht sales, from initial contact to close. There, I worked with inspectors, contractors, and other professionals in the marina. I learned how to work with a team of yacht specialists and took notes under Tony’s mentorship, applying all this knowledge to the process of buying my own sailing yacht.

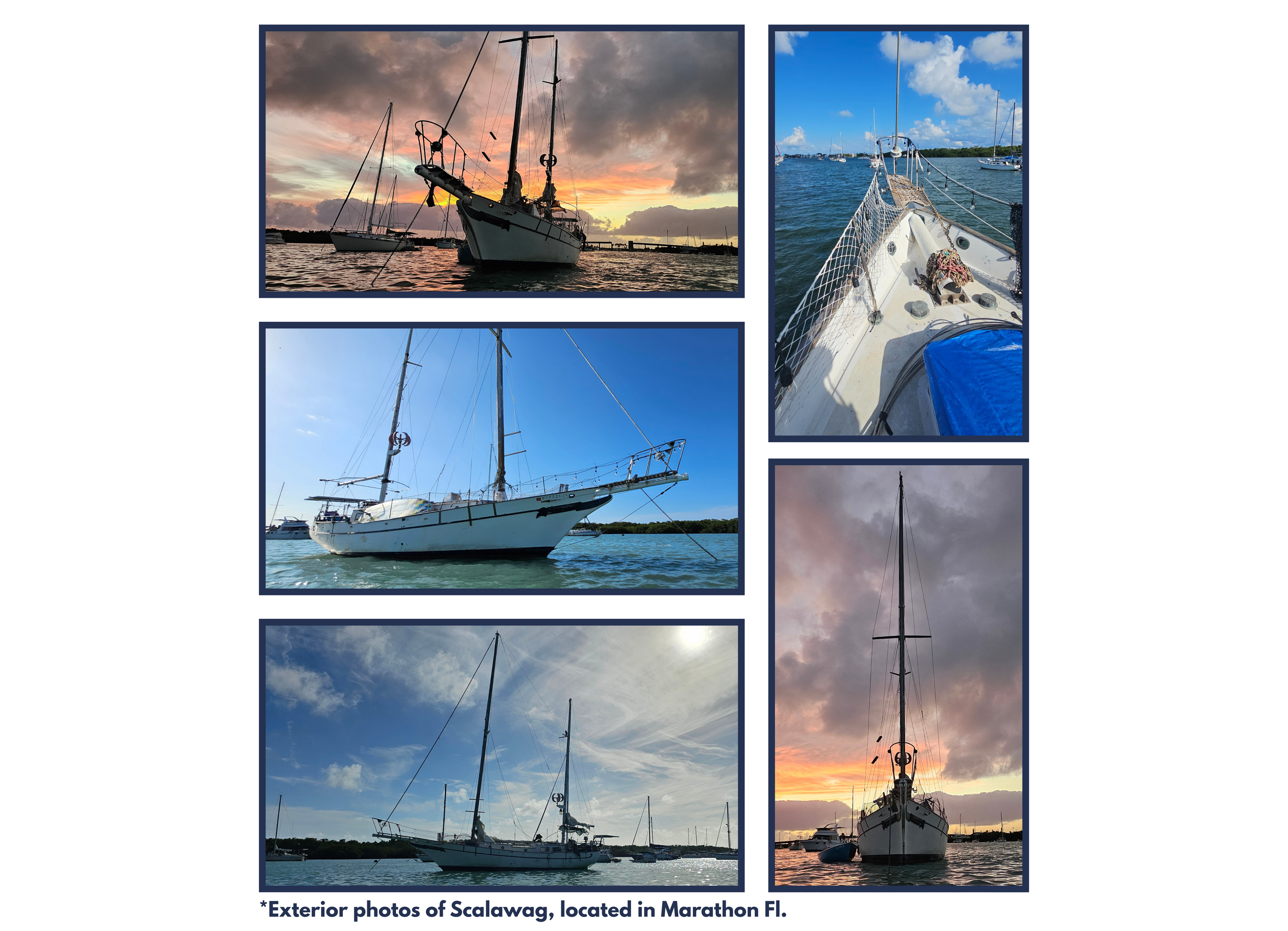

After leaving the Annapolis Boat Show, I was told by multiple captains about the Formosa brand. During this time, I found a listing in Boot Key Harbor for a 1977 Formosa Sea Tiger. Over the course of a few days, I asked multiple questions to the current owner, including the condition of the rigging, woodwork, motor, last use, and current use. He explained it had been a liveaboard sailboat for his family, and after upgrading to a 65-foot ketch, they needed to sell their previous vessel. This opened an opportunity to negotiate. With a clear reason to sell and a manageable expectation, he agreed to cut the price to 50% of the original listing if I made it there within the week.

That’s when I began my journey south. After driving through a storm, making a few stops to visit family and inspect other boats, my 1,000+ mile trip ended in Boot Key Harbor, Marathon, Florida.

After buying the boat, I flew up to New Jersey for multiple work events, then returned to Florida for a family Christmas. I spent the following week gathering and buying materials for my initial move aboard. By the time I was driving back down to the boat, it had been three weeks since closing. During that time, I did deep research into the boat's background, tracking down information about the Yankee Clipper and Atlantic Clipper name variants, identifying the builder as the Formosa Boat Building Co. in Taiwan, and learning more about its construction methods. This was my first time staying in the Florida Keys. The moving process also took proper research and planning.

I already knew it was a full fiberglass hull with a teak deck, though this deck had been removed by the previous owner, which was something I would have done anyway to avoid common issues and modernize the function and appearance of the deck. Many times growing up, I had dreamt of owning a boat like this. I used to spend hours watching videos, studying articles, and reading forums. In later years, I even assisted in the sale or demo of assets that I dreamed of buying, just as a professional fan. Thanks to the amount of information online, and having grown up in the digital age, I was able to consolidate years of research in those three weeks. By the time I returned, the owner and I were trading facts about the boat with other owners, and even educating them on my new purchase.

The Formosa Boat Building Co., founded in the early 1970s, was part of a wave of Taiwanese shipyards that gained recognition for producing solid, handcrafted fiberglass cruising yachts. During this period, Taiwan became a major hub for boat building, supported by skilled artisans, access to quality teak, and efficient production methods. Many of Formosa’s models were influenced by classic American and European sailing vessels. Their yachts often featured clipper bows, full keels, and detailed teak interiors, and became popular among long-distance cruisers. These sailing yachts have been used in movies and television for years as a symbol of wealth, or even as part of the hero’s journey. Movies like 50 First Dates, Wedding Crashers, and Captain Ron were all Formosa-built boats. This made the boat not only familiar but recognizable. For example, during the purchase of Scalawag, multiple onlookers passed by taking pictures or commenting on the name and stature of the vessel. Even Florida's Fish and Wildlife officers commented on my boat’s popularity as they stopped me.

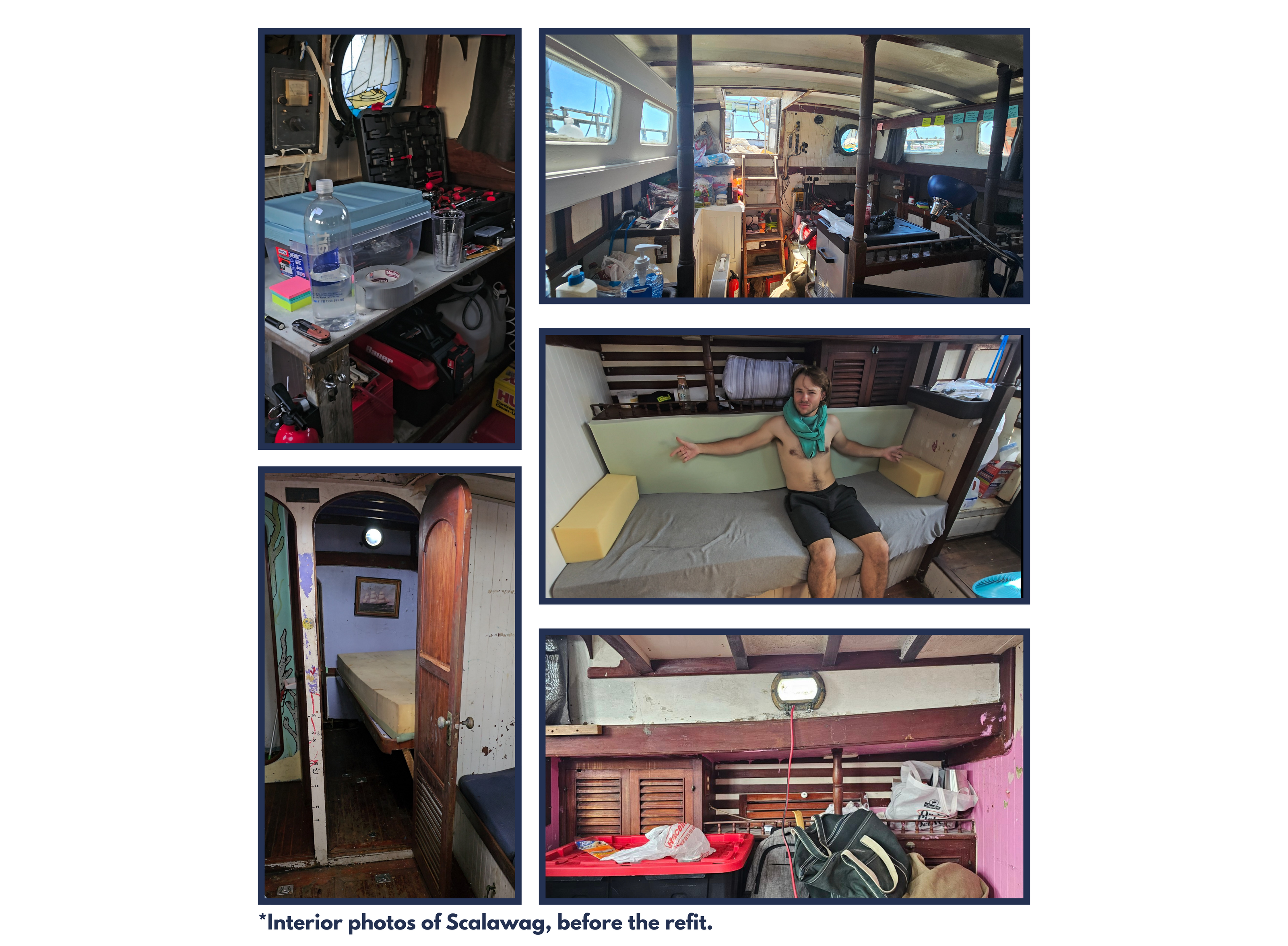

The restoration process began with passion and optimism. As soon as I got back, I started by cleaning and sanding every surface, both interior and exterior. This took the better part of three months. My goal wasn’t just to restore the boat to its original condition, but to put my own stamp on it. I wanted a cleaner, lighter interior that reflected my vision for the boat's next chapter. While this sounds fine on paper or even as I write it out, I am reminded of the hundreds of hours on my hands and knees just restoring the boat back to zero.

As I worked, I was reminded of my early days in the industry. My mentor, Dave Cherubini, had introduced me to the Formosa Sea Tiger back in 2015. On my first tour of his facility, I was shown the refit being performed on this vessel. I had worked on a 1973 Formosa Sea Tiger during my time at Cherubini Yacht Builders, and those months of sanding, hard labor, and repairs had prepared me well for this project. The experience had ingrained in me a deep appreciation for the craftsmanship of Formosa yachts. Now, as I restored Scalawag, I felt a deep connection to that history and my own 1977 Formosa Sea Tiger.

My mentorship with Dave Cherubini was the perfect training for the first six months of the renovation. While the bones of the boat were strong and the craftsmanship still intact, the condition posed a serious challenge early on. Multiple rounds of cleaning by hand, with power tools, and harsh chemicals were followed by dozens of sanding passes with varying grits.

During this time, I remembered Dave’s insistence on never cutting corners. If something needed sanding, it should be touched five different times with five different grits. As a high schooler, I hated hearing that. I just wanted to finish up and go home. But Dave would have me redo surfaces, make proper revisions, and instill in me the discipline to slow down and do things right.

That eye for quality became a standard I would later apply to every detail of Scalawag. While I didn’t plan to cut corners, I came to realize that maintaining the level of quality I had been taught, the level that resembled Cherubini craftsmanship, was non-negotiable. That mindset added months to the restoration timeline, but by the time the first major stages were complete, the result was clear.

I looked around and saw a yacht built to the standards I had grown up with, but done by my own hands. That realization gave the project meaning and reignited my passion. It wasn’t just a renovation. It was my moment to leave a mark. If I was going to build a name as a yacht company owner and as an apprentice of a long-standing builder, I had to own that legacy and shape it myself. That is where Osprey Yacht Company was born, on a 50-foot ketch, by a 23-year-old sanding during a storm.

Scalawag’s refit continues to this day. While the renovation is completed, I am now in the phase of modernizing the boat while preserving its original style and soul. This is where I truly get to add my own ideas and vision, not just as an owner, but as someone with a clear perspective on where the maritime and yacht manufacturing industry should be headed.

All of Osprey Yacht Company, from the website to the clothing line, to the on-water experiences and video production, was built entirely aboard Scalawag. Through the use of Starlink and modern onboard systems, everything has been designed, managed, and executed from the deck and cabin of a 50-foot ketch. This is the standard for Osprey Yacht Company: to not only imagine what the future of yachting could be, but to live and operate it in real time.

The focus now is on integrating features that I believe should already be standard when purchasing a 50-foot sailing yacht. In the 21st century, no one should have to worry about running out of fresh water or electricity while underway. With the technologies now available, there is no excuse for manufacturers to skip over these fundamentals. The same tools that are accessible to a small, independent yacht company like mine should be the baseline for every new build, especially by industry leaders with far greater resources.

Scalawag continues to be both a place of work and a source of happiness. It is where I entertain friends and family, test new ideas, and push boundaries. Every system added, every feature updated, reflects what I believe the future of cruising should look like: practical, efficient, and designed with real sailors in mind.

You can follow along with the progress and evolution of Scalawag right here on the website.